Services

MEHLER

Services

In addition to the production of technical yarns and fabrics, our offer includes a powerful service offering that adds essential value to your business and minimizes your risks.

In terms of quality conformance with product specifications, we have established state-of-the-art quality control procedures to ensure that our product quality meets the specifications and always remains at the same high level.

In addition, we manage the regional and global supply chain of hundreds of raw materials. To make sure that our products are available on time, whenever customer needs them.

TECHNICAL SUPPORT

Throughout the product life cycle we provide technical support and expertise advise on our products and solutions. Before a product leaves our site, we carefully check whether the product quality meets the specification requirements. In case of any technical issues during downstream processes or end-use, our well-trained technical experts are available to help and to solve problems. This includes lab testing, analysis and on-site support. Our customers buy not just a product, but all the technical and related services. Just contact us.

LAB SERVICES

We are the right partner for laboratory tests of technical textiles and related raw materials such as raw yarns and chemicals. We use state-of-the-art laboratory equipment to carry out basic tests as well as highly specialized tests and analyses. Every order is tested and approved in advance before being delivered and the test results are documented in quality test certificates which are handed over to the customer. Our lab experts also provide the laboratory support our customers need in order to conduct their day-to-day business efficiently and to achieve their product research, development, and quality goals. Our experienced lab experts guarantee reliable and fast results. If you are interested in our lab analysis program, please contact us.

Take a look at some of our lab tests:

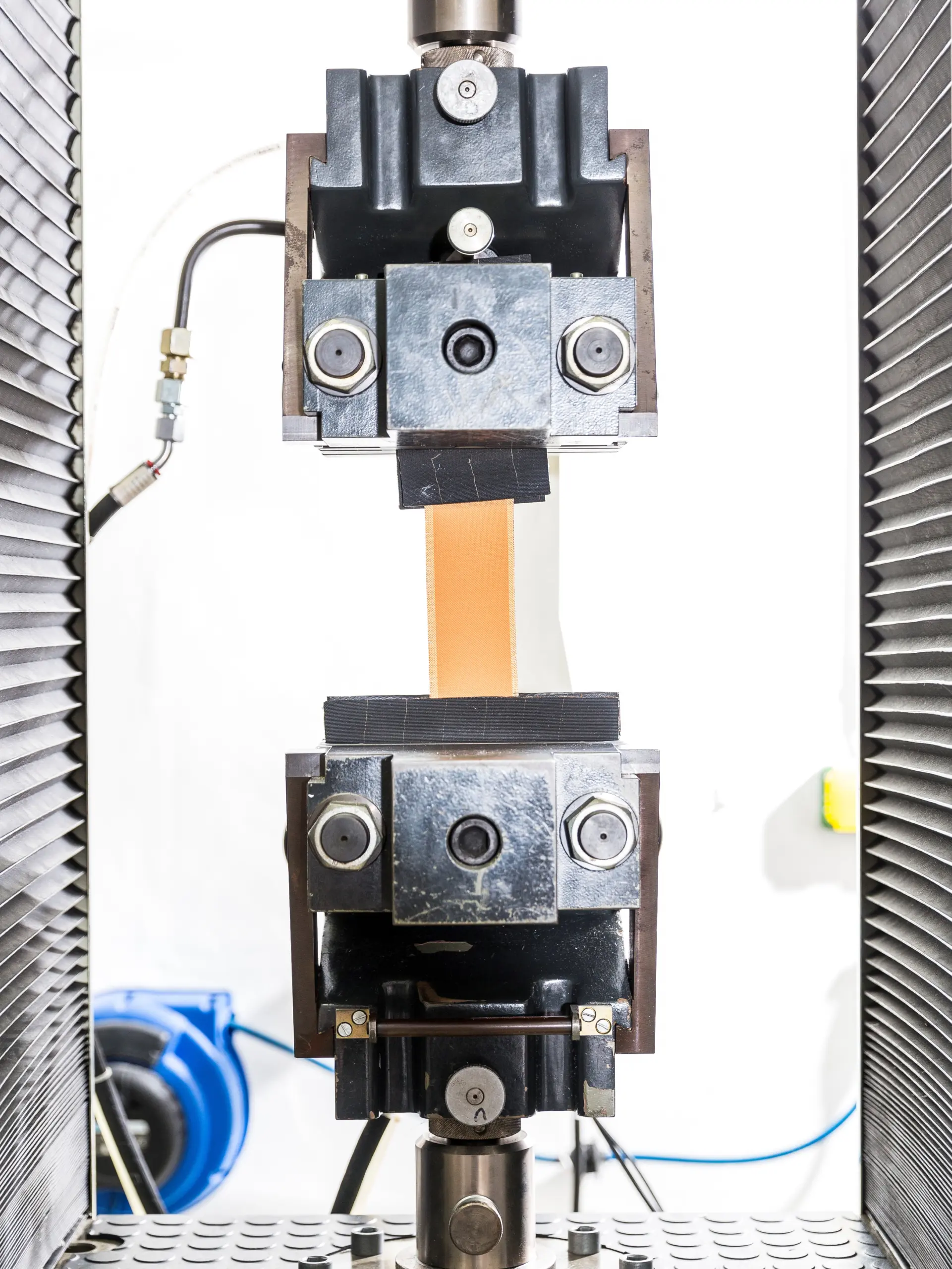

Tensile Strength Test

During the tensile test, the sample is slowly stretched at a defined speed. The resulting change in length and applied force is recorded until the sample breaks. In addition, hysteresis tests can be performed.

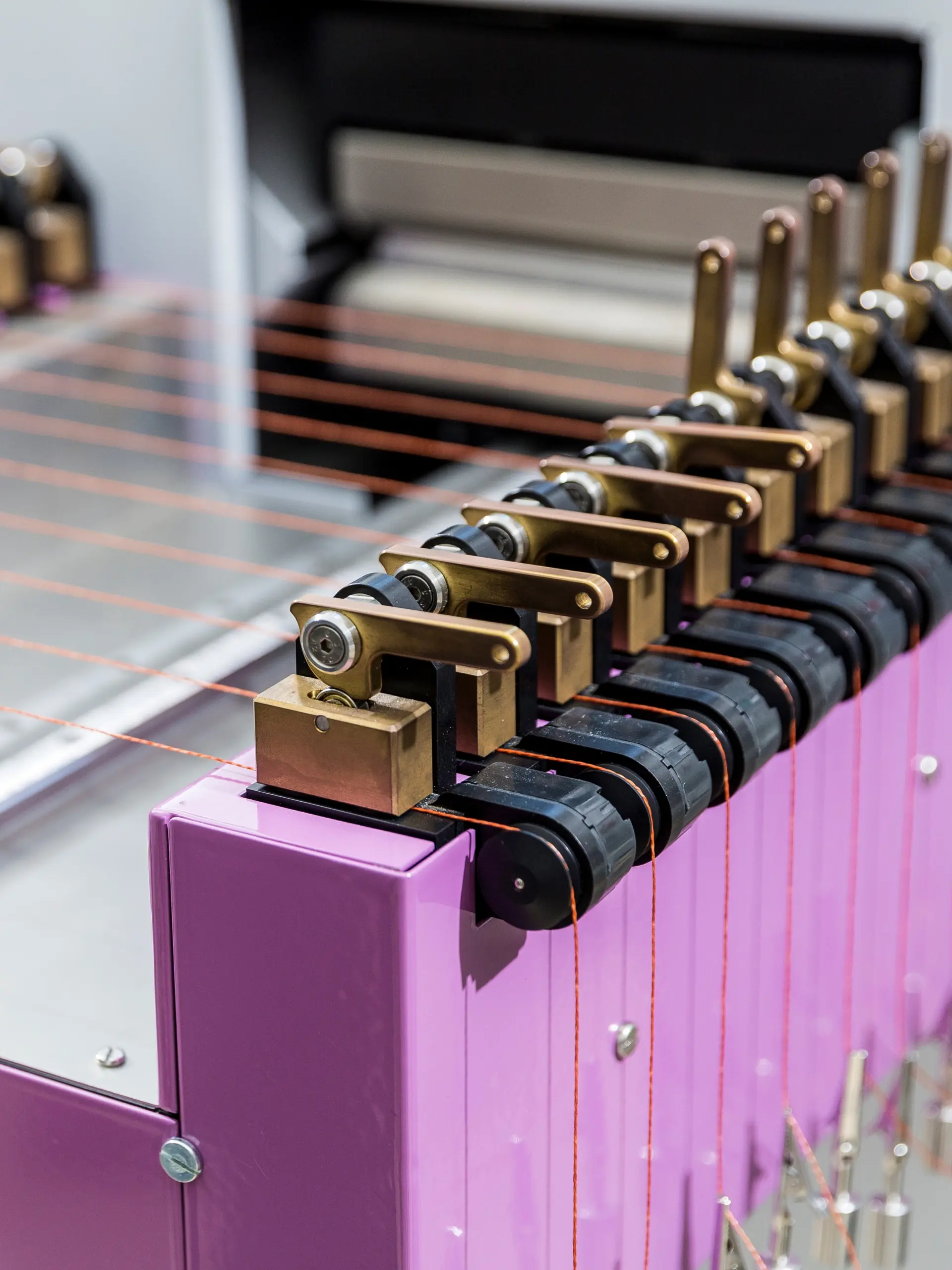

Shrinkage test

The shrinkage test identifies the shrinkage of textile samples exposed to defined temperatures Both the thermal shrinkage and/or the shrinkage force can be determined by heating the textile samples. The shrinkage is measured as a change in length in percent [%] and the shrinkage force in Newton [N].

Dip Pickup Test

The dip pickup can be measured with time-domain TD-NMR technology, because the signals from the dip and fiber are well separated and the signal amplitude correlates to the dip pickup.

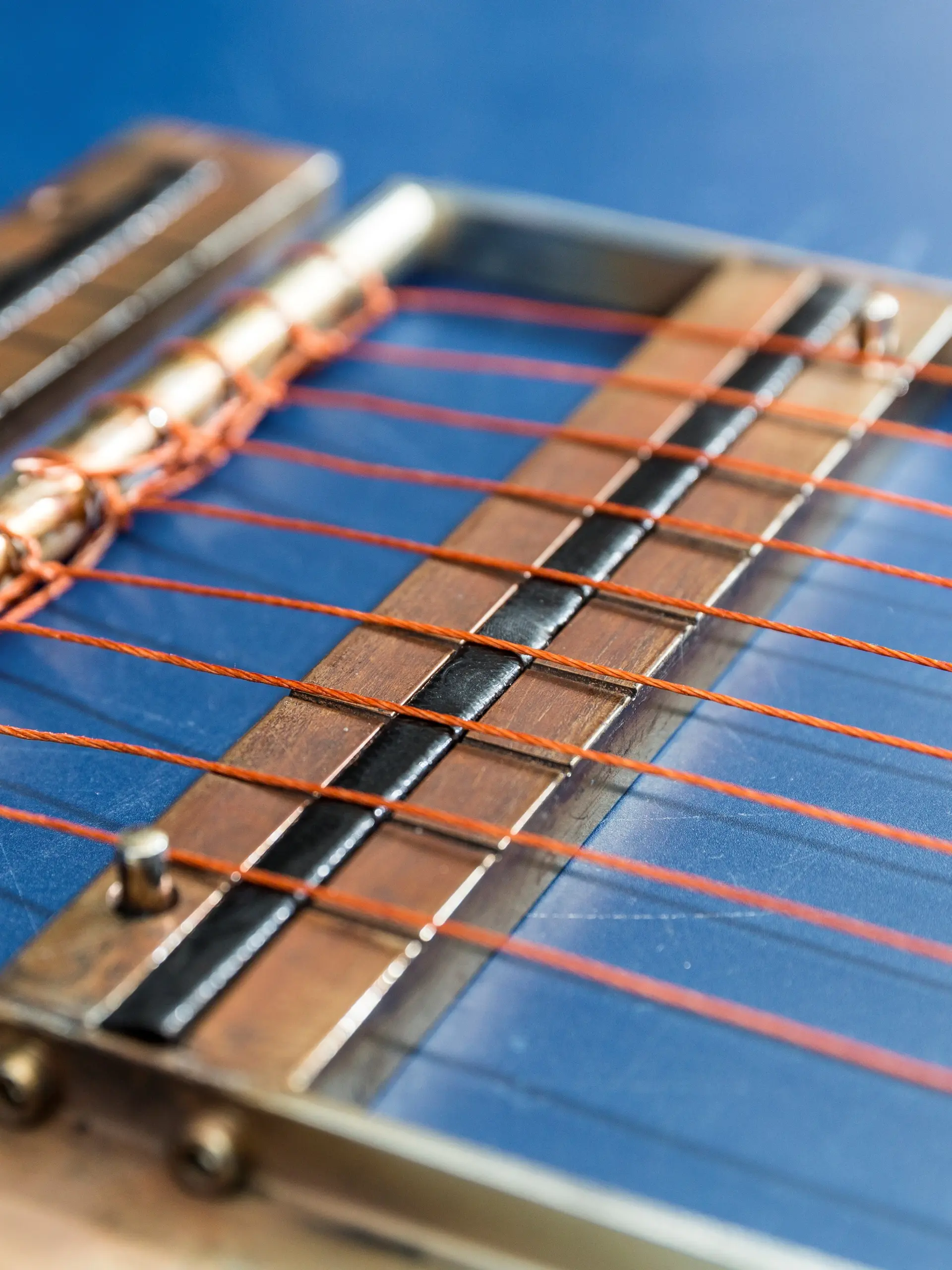

Adhesion T-Test

The degree of adhesion of the yarn to the rubber compound is measured by the T-Test. Based on the embedded length of the yarn, a certain amount of force is required to pull the yarn out of the composite structure. This force is the relevant parameter to determine the degree of adhesion of single end cords.

Adhesion Peel Test

The peel test measures the adhesion of yarn or fabric samples to a particular type of rubber or other materials. Two textile and rubber layers are pulled apart.

IR-Spectroscopy

Infrared spectroscopy is a physical analysis method which is used to determine and identify a wide variety of substances.

Thermal gravimetric analysis

This test measures the mass of a sample over time as the temperature changes. The results show physical phenomena, such as phase transitions, absorption, adsorption and desorption; and chemical phenomena including chemisorptions, thermal decomposition, and solid-gas reactions (e.g. oxidation or reduction).

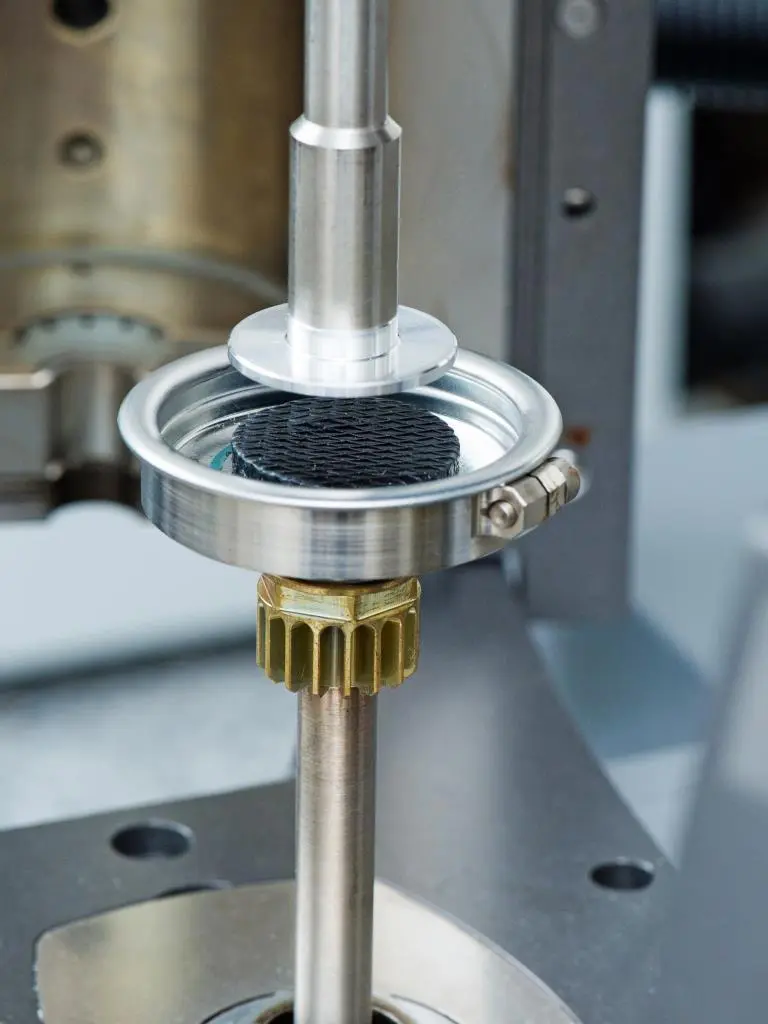

Rheometer

Used to measure the manner in which a liquid, suspension or slurry flows in response to applied forces. It is used for those liquids which cannot be defined by a single viscosity value and therefore require more parameters to be set and measured than is the case with a viscometer. It measures the rheology of the sample.

Microscopy

Used to display and document areas of objects that are invisible to the naked eyes. Used e.g. for damage analysis of samples.

PRODUCT DEVELOPMENT

MEHLER is a strong development partner and highly committed to playing a key role in innovation. We see that megatrends will disrupt some markets with complete new technologies over the next few years. Technical textiles will play an increasingly important role in such developments. MEHLER has a unique team of research and development experts, a strong innovation network and is well positioned and already fully involved in these developments.

Product Development includes small product modifications, e.g. to optimize product performance in a downstream process as well as completely new technical textiles that are used for new technologies such as e-cars. We operate our Product Development in Fulda/Germany and in Famalicão/Portugal.

Every time we develop a product, we work closely with our customers to manage project goals, time, resources and any kind of deviations. Our Product Development process -from the original idea to sampling, piloting and serial production- is standardized and highly efficient to meet the requirements and to minimize time-to-market.